Double Cone Mixer

Product description

The double-cone mixer is a powder mixing equipment used in the

pharmaceutical, chemical and other industries. It is composed of

symmetrical conical shells connected by a central axis to form a

"double-cone" shape. During operation, the motor drives the

cylinder to rotate around a horizontal axis. Under the influence of

gravity and centrifugal force, the materials fall and spread,

achieving uniform mixing. It has high mixing efficiency, low

residue, strong adaptability, and its inner wall is polished to

reduce adhesion. Some models can be equipped with a vacuum system,

and it is suitable for mixing dry powders, granules, etc.

Working principle

The working principle of the double-cone mixer is that the motor

drives the double-cone cylinder to rotate 360° around the

horizontal axis. Under the combined action of gravity and

centrifugal force, the materials inside the cylinder constantly

undergo overturning, diffusion, convection and shear movements

within the cone. Through repeated aggregation and dispersion

processes, the agglomerations are broken, and finally, a uniform

mixture of multi-component materials is achieved.

Product characteristics

1. High uniformity of mixture: Through the rotation of the

cylinder, the materials are flipped and mixed by convection,

reducing local stagnation. It is particularly suitable for the

uniform mixing of multi-component powders or granular materials.

2. Little residue, easy to clean: The conical structure design

reduces dead corners, and the inner wall is polished, resulting in

less material adhesion. The subsequent cleaning is more convenient,

meeting the hygiene requirements of industries such as

pharmaceuticals and food.

3. Strong adaptability: It can handle dry powders, granules and

low-viscosity materials. Some models, when equipped with a vacuum

system, can also be used for drying and mixing of heat-sensitive

materials, providing a wider range of applications.

4. Stable operation, low energy consumption: The structure is

simple, without complex stirring components. During operation, it

has low vibration and low noise, and the energy consumption is

relatively more economical compared to traditional stirring-type

equipment.

Application

1. New energy: The cathode material of lithium batteries (lithium

iron phosphate) is mixed with conductive agents to ensure battery

performance.

2. Food: Infant formula is a blend of vitamins and milk powder,

which causes low damage and leaves little residue, meeting food

hygiene standards.

3. Chemical engineering: When the catalyst is mixed with the

binder, a spray device can be installed to achieve solid-liquid

integration.

4. Ceramics: Mix barium titanate powder with MLCC to ensure

consistency in dielectric constant.

5. Agricultural: Wettable powder is mixed in batches, sealed to

prevent leakage, and the unloading efficiency is high.

6. Research and Development: Small-batch new material formula

research and development in the laboratory, supporting flexible

parameter adjustment.

Product parameter

| Model | W-300 | W-500 | W-1000 | W-1500 | W-2500 | W-4000 | W-6000 | W-8000 |

Production capacity (kg/time) | 150 | 250 | 500 | 750 | 1250 | 2000 | 3000 | 4000 |

Full volume (cubic meter) | 0.3 | 0.5 | 1 | 1.5 | 2.5 | 4 | 6 | 8 |

Mixing time (min) | 4-8 | 4-8 | 6-12 | 6-12 | 6-12 | 6-15 | 6-15 | 6-15 |

Motor power (KW) | 1.1 | 2.2 | 3 | 4 | 5.5 | 7.5 | 11 | 15 |

| Cylinder speed (RPM) | 15 | 15 | 12 | 12 | 12 | 10 | 10 | 10 |

Dimension (L*W*H) | 1680*650 *1600 | 2080*750 *1900 | 2150*850 *2100 | 2300*1600 *3100 | 2500*1000 *2450 | 2980*1580 *2800 | 3500*1800 *3000 | 3980*2000 *3200 |

| Weight (kg) | 310 | 550 | 800 | 950 | 1650 | 1880 | 2350 | 2680 |

Detail display

Product display

Packaging & Shipping

Why choose us

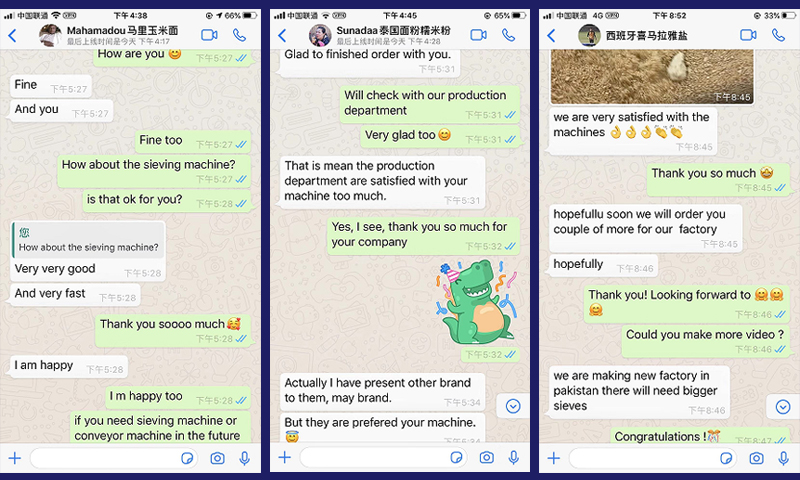

About us

Company Profile

We have been specializing in the production of Screening and

conveying equipment for 13 years. China's vibrating screen industry

top three. And we have done matching and OEM for many large

companies. Including the world's top vibrating screen manufacturer,

Sweco, USA, we have OEM for his China region. And our products are

often exported to Australia, Thailand, Indonesia, New Zealand and

other countries.