Linear Vibrating Screen

Product description

The linear screen is an efficient equipment that utilizes the

linear vibration generated by the vibration motor to achieve the

separation of materials.

It is composed of a sieve box, a vibration motor, a vibration

damping system, etc. The materials move linearly along the sieve

surface and are separated into products of different particle sizes

through different mesh sizes of the sieve net. It has the

characteristics of high screening accuracy, large processing

capacity, and low noise. It is widely used in industries such as

mining, building materials, chemical industry, and grain industry,

and is suitable for the classification or impurity removal of dry

and loose materials.

Working principle

The core working principle of the linear screen is that the

vibration motor drives to generate directional linear vibration,

which in turn drives the screen box and the screen mesh to perform

periodic reciprocating motion.

After entering the sieve surface through the feed port, the

materials will jump and move forward uniformly along the sieve

surface under the force of linear vibration. During this process,

the materials smaller than the sieve mesh size (the materials below

the sieve) will pass through the sieve and fall into the receiving

port below, while the materials with a larger size (the materials

above the sieve) will continue to move forward and eventually be

discharged from the end of the sieve surface, thus completing the

classification or separation of the materials.

Product features

1. Sorting Accuracy: Linear vibration prevents material

accumulation, the screen mesh can be customized, and the

classification accuracy is high;

2. Processing Capacity: Compatible with different production

volumes, capable of meeting small and medium batch to large-scale

continuous production;

3. Stable Operation: With a vibration damping system, it has low

noise, low wear, and low maintenance costs;

4. Wide Applications: Compatible with drying loose materials,

applicable to multiple industries such as mining, chemical

industry, and grain industry.

Product parameter

| Model | Layer | Screening

Area(mm) | Mesh size(mm) | Particle

Size(mm) | Capacity(t/h) | Power

(kw) | Double Amplitude(mm) |

|

| DZSF-612 | 1 to 5 | 600*1200 | 0.02-20 | ≤20 | ≤3 | 0.37×2 | 6 to 10 |

| DZSF-520 | 1 to 5 | 500*2000 | 0.02-20 | ≤20 | ≤5 | 0.37×2 | 6 to 10 |

| DZSF-525 | 1 to 5 | 500*2500 | 0.02-20 | ≤20 | ≤8 | 0.37×2 | 6 to 10 |

| DZSF-1020 | 1 to 5 | 1000*2000 | 0.02-20 | ≤20 | ≤12 | 0.75×2 | 6 to 10 |

| DZSF-1025 | 1 to 5 | 1000*2500 | 0.02-20 | ≤20 | ≤16 | 0.75×2 | 6 to 10 |

| DZSF-1030 | 1 to 5 | 1000*3000 | 0.02-20 | ≤20 | ≤20 | 1.1×2 | 6 to 10 |

| DZSF-1224 | 1 to 5 | 1200*2400 | 0.02-20 | ≤20 | ≤23 | 1.5×2 | 6 to 10 |

| DZSF-1525 | 1 to 5 | 1500*2500 | 0.02-20 | ≤20 | ≤28 | 1.5×2 | 6 to 10 |

| DZSF-1530 | 1 to 5 | 1500*3000 | 0.02-20 | ≤20 | ≤32 | 2.2×2 | 6 to 10 |

Production line diagram

1.Forklift filling the material into the storage hopper

2.A belt conveyor under the hopper, to transport the material to a

linear vibrating screen

3.And another belt conveyor can transport the sieved material to

other place

4.The belt conveyor can with dust cover and can add wheels

Product details

Product shows

Application

Packaging & Shipping

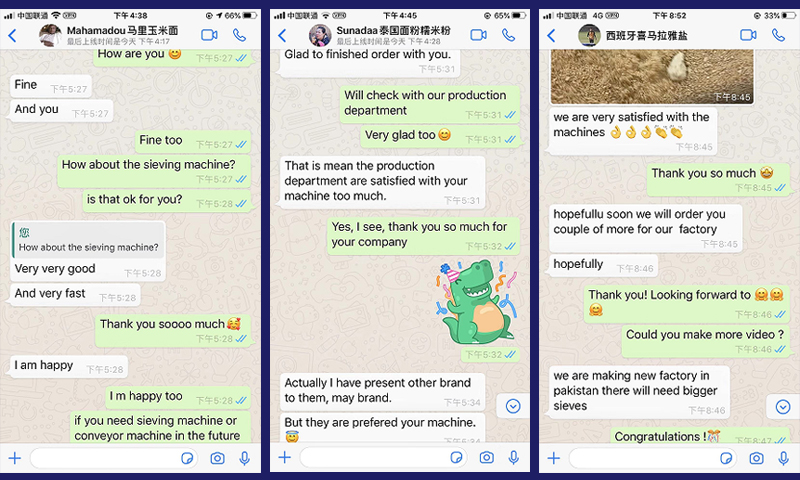

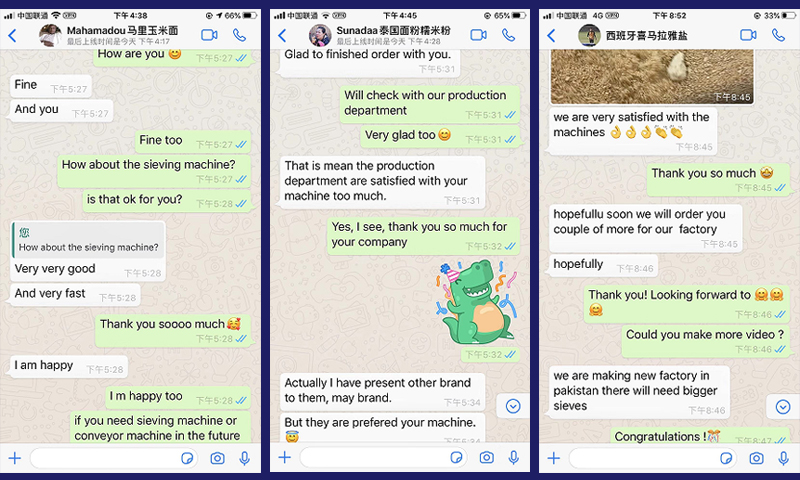

Why Choose us

About us

We have been specializing in the production of Screening and

conveying equipment for 13 years. China's vibrating screen industry top three. And we have done

matching and OEM for many large companies. Including the world's top vibrating screen manufacturer,

Sweco, USA, we have OEM

for his China region. And our products are often exported to

Australia, Thailand, Indonesia, New Zealand and other countries.

We welcome customers or dealers to visit our factory and will

arrange everything for you.Our factory address: West of the industrial and commercial office of Da

Zhaoying Town, Xinxiang City, Henan Province.