The Z-shaped conveyor has significant advantages. It has a high

conveying

efficiency and can operate continuously, meeting the needs of

large-scale

production; it has sealing performance, effectively preventing

material leakage and

dust flying, ensuring a clean production environment; it has a

simple structure, and

each component is easy to disassemble and install making daily

maintenance

convenient and greatly reducing operation and maintenance costs; it

has strong

adaptability to materials, whether it is powder materials such as

flour and cement,

or gran and block materials such as grain and ore, it can be stably

conveyed.

When the Z-shaped hoist is in operation, the power supply is

connected, and the

motor begins to work, with the high-speed generating power that is

transmitted

through the reducer to achieve speed reduction and torque increase,

and then

accurately transmitted to the drive shaft. The sprocket or drum on

the shaft works

closely with the chain and conveyor belt connected to the hopper,

causing them to

start a circular motion. Materials enter from the feed port, and

the inclined and

guide structure of the feed port allow the materials to flow evenly

and smoothly.

When the hopper runs to the feed port, the materials naturally fall

into it under

action of gravity. The hopper, filled with materials, is steadily

lifted along the

Z-shaped track under the traction of the chain or conveyor belt.

The speed can be

flexibly adjusted according to actual needs through the frequency

converter. When

the hopper reaches the top turning point, the direction of motion

suddenly changes,

and the materials affected by inertia and gravity, have a tendency

to move towards

the discharge port. At the same time, the discharge scraper and

other devices at the

top work together to the materials completely discharge and

smoothly enter the

subsequent process, thus completing the entire process of material

lifting.

1. Efficient conveying: The Z-shaped lifting machine can achieve

continuous and

uninterrupted material conveying, with large conveying capacity,

which can meet

the needs different production scales.

2. Space-saving: The unique Z-shaped structure makes the lifting

machine occupy

less space in the vertical direction, especially suitable for use

in places where

factory space is limited.

3. Good sealing: The overall closed design effectively prevents

material leakage and

dust flying during the conveying process, ensuring the quality of

the materials and the

working environment.

4. Simple maintenance: The structure is relatively simple, and the

installation and

removal of various parts are convenient, making daily maintenance

and inspection

work easy carry out, reducing the maintenance cost and downtime of

the equipment.

| Model | HYZT-2L | HYZT-3L | HYZT-5L | HYZT-7L | HYZT-10L |

| Capacity | 0-6m3/h | 0-8m3/h | 0-12m3/h | 0-15m3/h | 0-20m3/h |

| Bucket Volume | 2L | 3L | 5L | 7L | 10L |

| No.s of discharge port | Single | Single or Muti-discharge port |

| Lifting Height | Up To 50m | Up To 50m | Up To 50m | Up To 50m | Up To 50m |

| Power | 0.75-22KW | 0.75-22KW | 0.75-22KW | 0.75-22KW | 0.75-22KW |

| Voltage | As per order |

| Construction materials | Carbon steel, SS304/316 |

| Bucket materials | Food grade PP or ABS, SS304/316, Carbon steel |

Company Profile

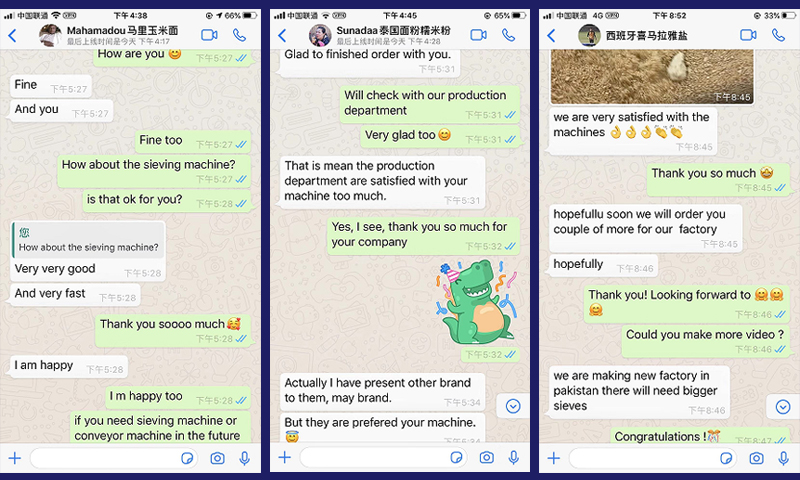

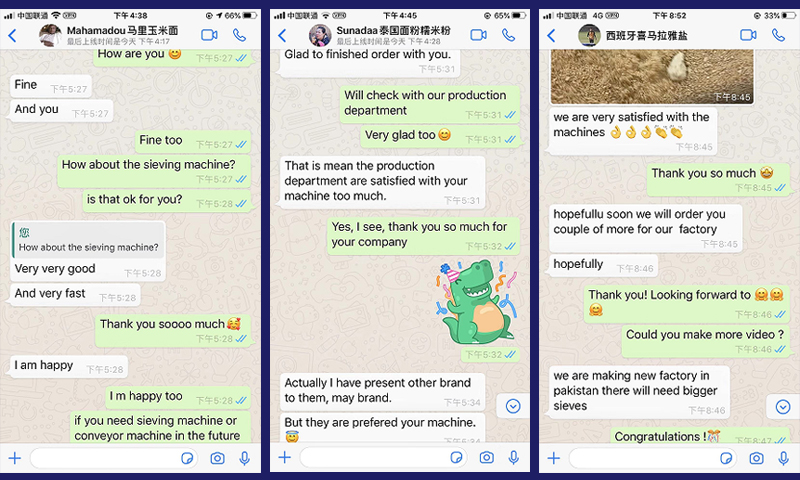

We have been specializing in the production of Screening and

conveying equipment for

13 years. China's vibrating screen industry top three. And we have

done matching and

OEM for many large companies. Including the world's top vibrating

screen manufacturer,

Sweco, USA, we have OEM for his China region. And our products are

often exported to

Australia, Thailand, Indonesia, New Zealand and other countries.

We welcome customers or dealers to visit our factory and will

arrange everything for you.

Our factory address: West of the industrial and commercial office

of Da Zhaoying Town,

Xinxiang City, Henan Province.