V-Type Mixer

Product Description

The V-shaped mixer is a capable assistant for material mixing, and

its unique V-shaped cylinder design is key to its efficient

operation. It is made of carbon steel, which is strong and durable,

and the parts that come into contact with the materials are made of

stainless steel, ensuring that the materials remain pure free from

contamination. With the motor and reducer working together to

provide stable power, the speed and mixing time can be precisely

regulated through the intelligent control system. During operation

the materials rotate with the cylinder, producing complex

movements, combining vertical rolling with horizontal convection

and diffusion, and quickly mixing evenly. Some models are also

equipped with a system, which is specially designed to handle

materials that are prone to oxidation and moisture absorption. Due

to its outstanding performance, it is widely used in many

industries such chemical, food, and pharmaceutical, helping various

industries to produce efficiently.

Working Principle

When the V-shaped mixer is working, the motor provides the initial

power, which is precisely regulated through the reducer, converting

it into the appropriate and torque to drive the V-shaped cylinder

to rotate evenly. During the rotation process, the materials inside

the cylinder will rise with the cylinder, and when they reach a

height, they will naturally fall due to gravity, completing the

vertical up and down rolling, achieving preliminary mixing. At the

same time, the special shape of the V cylinder causes the materials

to have different speeds and directions of motion at different

parts, forming horizontal convection and diffusion, such as the

materials in the two arms of the shape meeting and blending at the

bottom during rotation. This synergistic effect of vertical and

horizontal motion continuously strengthens the mixing between

materials, thus efficiently achieving the effect of mixing.

Features & Advantage

1. Efficient and uniform mixing: The unique V-shaped cylinder

structure allows materials to produce vertical rolling and

horizontal convection and diffusion during, which can fully mix

different materials in a short time, with high uniformity of

mixing. Typically, a batch of material mixing can be completed in

1030 minutes.

2. Compact and reasonable structure: The V-shaped design not only

improves mixing efficiency but also makes the overall structure of

the equipment compact, occupying a space, which is convenient for

installation and layout in various production workshops and can

adapt to different scales of production sites.

3. Safe and durable material: The main is made of carbon steel,

which ensures strength and stability, reduces costs; the parts in

contact with materials are made of stainless steel, which has

strong corrosion resistance, the sanitary standards of food,

pharmaceutical and other industries, and ensures that materials are

not contaminated.

4. Simple and intelligent operation: Equipped with advanced control

system, can easily achieve start, stop, speed regulation and other

operations, and can also accurately preset mixing time and speed

according to the characteristics of materials and production needs,

to automated production.

5. Rich and diverse functions: In addition to the conventional

mixing function, some models are equipped with vacuum systems,

which can effectively handle materials that are to oxidation and

moisture absorption, and meet the mixing needs of special

materials.

6. Wide range of applicable industries: Strictly follow the

mechanical industry standards, and have performance in many

industries such as food, pharmaceutical, chemical, feed, etc., and

can adapt to the material characteristics and production process

requirements of different industries.

Product Parameters

| Model | V-30 | V-100 | V-200 | V-300 | V-500 | V-1000 | V-1500 | V-2000 | V-3000 | Total volume

(L) | 10-30 | 100 | 200 | 300 | 500 | 1000 | 1500 | 2000 | 3000 | | Effective volume

(L) | 5-15 | 50 | 100 | 150 | 250 | 500 | 750 | 1000 | 1500 | | Maximumloading

weight (kg) | 5-20 | 40 | 80 | 120 | 200 | 400 | 600 | 800 | 1200 | | Spindle

speed (RPM) | 29 | 1-12 | 1-12 | 1-12 | 1-12 | 1-12 | 1-9 | 1-9 | 1-9 | | Motor

power (kw) | 0.55 | 0.75 | 1.1 | 1.5 | 2.2 | 3 | 4 | 5.5 | 7.5 | | | Input power | 220V | 380V | 380V | 380V | 380V | 380V | 380V | 380V | 380V | Total turning

height (mm) | 1200 | 1500 | 1650 | 1800 | 2100 | 2400 | 2700 | 3000 | 3200 | | | Weight (kg) | 120 | 500 | 600 | 700 | 800 | 1000 | 1150 | 1400 | 2300 | Overall

dimension (mm)

L / w / h | 800*

400*

1200 | 1800*

600*

1500 | 2200*

650*

1700 | 2320*

720*

1800 | 2450*

720*

2000 | 3000*

900*

2300 | 3300*

1200*

2600 | 3800*

1200*

2900 | 4100*

1800*

3100 | | | | More sizes can be customized |

|

Details Lmages

Product Shows

Packing & Delivery

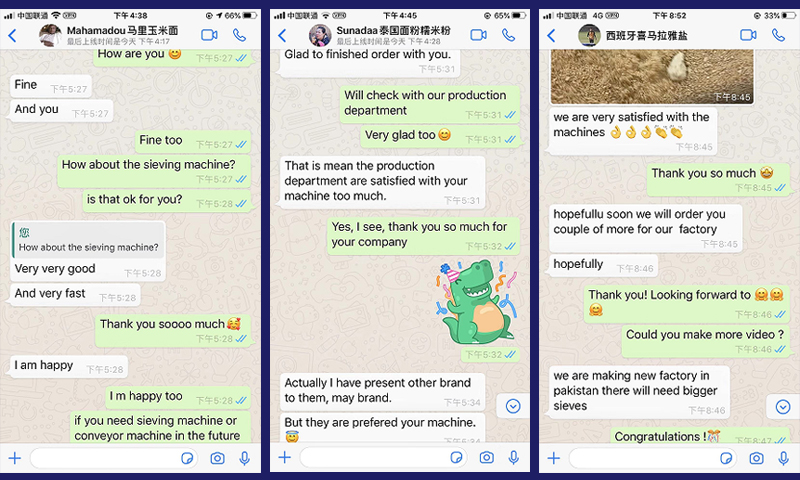

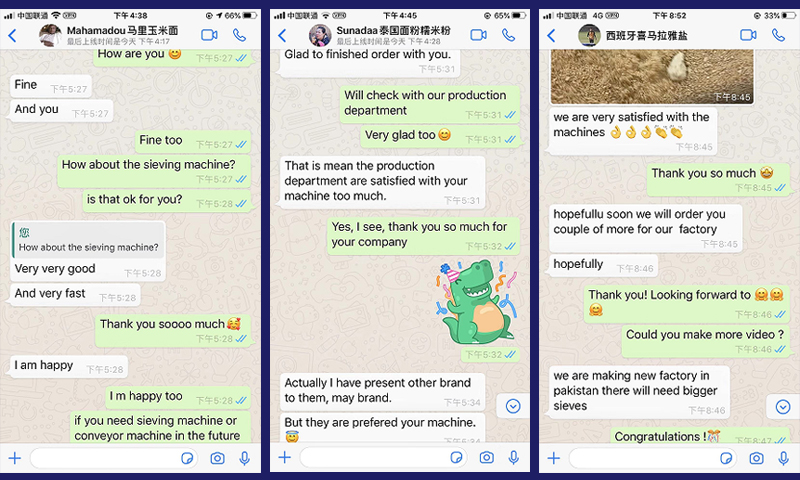

About us

Company Profile

We have been specializing in the production of Screening and

conveying equipment

for 13 years. China's vibrating screen industry top three. And we

have done matching

and OEM for many large companies. Including the world's top

vibrating screen

manufacturer, Sweco, USA, we have OEM for his China region. And our

products are

often exported to Australia, Thailand, Indonesia, New Zealand and

other countries.