Z Type Bucket Elevator

Product description

Z-type elevator in the industrial production to bear the key

material conveying responsibility. With its Z-shaped structure, it

cleverly integrates horizontal, inclined and vertical conveying

links, greatly saving space and adapting to the limited working

environment. When running, the motor drives the bucket belt, the

bottom bucket scoops the material, climbs along the Z-shaped

channel, and discharges the material by centrifugal force to the

top. It is highly inclusive to the material, whether it is grain

particles, or cement powder can be properly transported. Moreover,

the conveying capacity can be adjusted according to demand, good

sealing, prevent material leakage, smooth and quiet operation,

simple maintenance, widely used in grain storage, building

materials processing and other fields, laying a solid foundation

for efficient production in various industries.

Working principle

When the Z-type hoist is working, the motor starts first, drives

the drive shaft to operate, and drives the circular movement of the

bucket belt around it. The bucket at the bottom of the hoist will

penetrate deep into the material pile during operation. Due to the

unique shape and operation situation of the bucket, it can scoop or

scrape materials efficiently.

The bucket filled with material rises along the Z-shaped track with

the bucket belt. When passing through the curve, the material will

not be spilled by centrifugal force and its own gravity. When the

bucket reaches the top discharge port, the direction of movement

changes, and the material is poured out of the bucket by the

combined action of centrifugal force and gravity, and falls into

the designated position through the discharge port. This cycle

continues to complete the stable transport of materials from low to

high, horizontal and vertical directions.

Product characteristics

1. Unique layout: The Z-shaped structure of the Z-type elevator

enables it to achieve a combination of horizontal, inclined and

vertical conveying in a limited space, which is especially suitable

for use in places with narrow sites and limited space.

2. Smooth conveying: During the conveying process of the Z-type

hoist, the movement of the materials in the bucket is relatively

smooth, especially at the corner. Through reasonable design, the

impact and sprinkling of the materials can be effectively reduced.

3. A variety of material adaptation: more adaptability to the shape

and characteristics of the material, whether it is granular,

powdered or small block materials can be well transported. Compared

with the blockage problems that may occur when the screw elevator

transponds materials with large viscosity or high humidity, the

Z-type elevator is less affected by the characteristics of the

material.

4. Low noise operation: The operation of the Z-type elevator is

relatively quiet, due to its structural design and movement mode,

the noise generated during the operation is low, which can provide

quieter conditions for the working environment, which is conducive

to improving the working environment and reducing noise pollution.

5. Easy maintenance: The structure is relatively simple, the

installation and disassembly of the main components such as the

bucket and the bucket belt are more convenient, the daily

inspection and maintenance work is easy, the maintenance cost is

low, and there is no need to spend a lot of time and energy on

disassembly and assembly during maintenance.

6. Efficient conveying: Through the reasonable configuration of the

drive device and bucket specifications, the Z-type elevator can

achieve higher conveying capacity and lifting height, which can

meet the needs of different production scales. On some large

production lines, the Z-type elevator can play its unique

advantages to improve the efficiency of the entire conveying

system.

7. Continuous conveying: continuous and stable material conveying

can be achieved to ensure the continuity of the production process,

and the Z-type elevator can carry out material upgrading without

interruption, which helps to improve production efficiency and the

stability of product quality.

Product parameter

| Model | HYZT-2L | HYZT-3L | HYZT-5L | HYZT-7L | HYZT-10L |

| Capacity | 0-6m3/h | 0-8m3/h | 0-12m3/h | 0-15m3/h | 0-20m3/h |

| Bucket Volume | 2L | 3L | 5L | 7L | 10L |

| No.s of discharge port | Single | Single or Muti-discharge port |

| Lifting Height | Up To 50m | Up To 50m | Up To 50m | Up To 50m | Up To 50m |

| Power | 0.75-22KW | 0.75-22KW | 0.75-22KW | 0.75-22KW | 0.75-22KW |

| Voltage | As per order |

| Construction materials | Carbon steel, SS304/316 |

| Bucket materials | Food grade PP or ABS, SS304/316, Carbon steel |

Product details

Product display

Packaging & Shipping

Why Choose us

About us

Company Profile

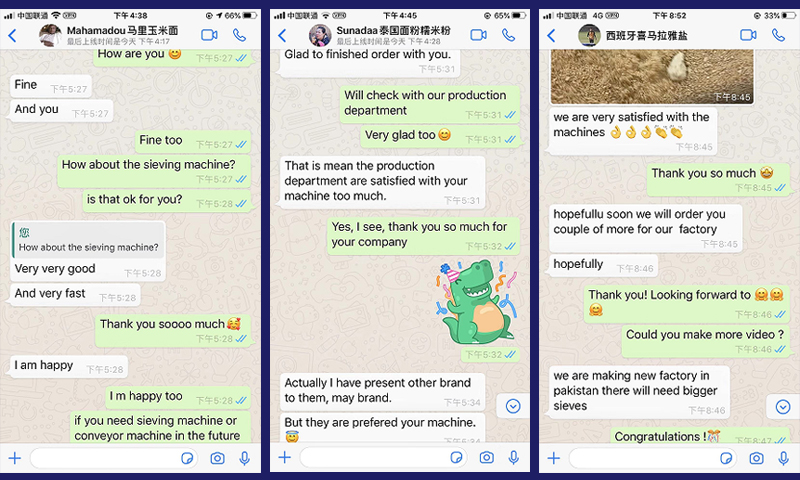

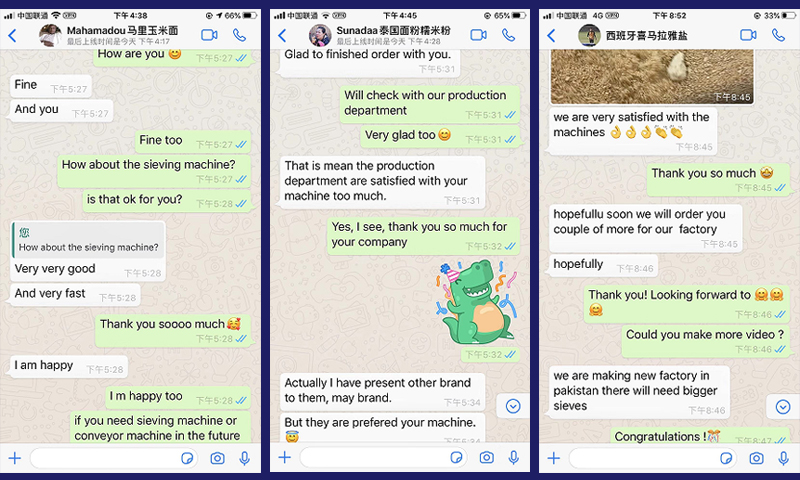

We have been specializing in the production of Screening and

conveying equipment for 13 years. China's vibrating screen industry

top three. And we have done matching and OEM for many large

companies. Including the world's top vibrating screen manufacturer,

Sweco, USA, we have OEM for his China region. And our products are

often exported to Australia, Thailand, Indonesia, New Zealand and

other countries.

We welcome customers or dealers to visit our factory and will

arrange everything for you. Our factory address: West of the

industrial and commercial office of Da Zhaoying Town, Xinxiang

City, Henan Province.