V-Type Mixer

Product Description

The V-type mixer is a common powder mixing equipment. Its main body

is composed of two cylinders welded in a V shape. During operation,

it rotates around a horizontal axis, causing the materials to

continuously undergo diffusion, convection and shearing mixing

inside the cylinders. It features high mixing efficiency, low

material residue, simple structure and easy operation. It is widely

applied in the uniform mixing operations of different materials in

industries such as chemical engineering, pharmaceuticals, and food.

Working Principle

The main body of the V-type mixer is formed by welding two

cylinders at an Angle of 80° to 90° into a V shape. The central

shaft runs through the vertex as the rotating hub. The equipment is

composed of a cavity, a rotating shaft, a drive device and a base.

Some models can be equipped with flying knife devices or inert gas

interfaces. The structure takes into account both efficiency and

operational convenience.

When the V-type mixer is in operation, the cavity rotates around a

horizontal axis, causing the materials to undergo triple mixing

effects of convection, diffusion and shearing within the V-shaped

cavity: convection mixing causes the materials to periodically

converge and climb between the two cylinders due to gravity;

diffusion mixing makes different particles micro-interpenetrate;

and shearing mixing breaks the lumps through friction and

compression.

Product features

1. Structural and mixing efficiency advantages

- Symmetrical V-shaped cavity: The 80° to 90° Angle design forms an

asymmetrical movement trajectory. During the rotation of the

material, intense convection and diffusion occur, resulting in high

uniformity of mixing, with few dead corners and low residue.

- Low resistance operation: The central shaft support structure is

stable. When rotating, the material is less affected by centrifugal

force, with lower energy consumption, making it suitable for

long-term continuous operation.

2. Material adaptability and functional scalability

- Wide applicability: It can handle powder and granular materials,

and has a remarkable mixing effect on materials with large density

differences and easy stratification. By configuring the flying

knife device, the caked materials can be crushed.

- Optional protective functions: Some models meet the mixing

requirements of flammable, explosive or oxidation-sensitive

materials, and comply with safety standards in the pharmaceutical,

chemical and other industries.

3. Ease of operation and cleaning

- Convenient regulation: The rotational speed and mixing time can

be precisely adjusted according to the characteristics of the

materials. It features a high degree of automation and supports PLC

program control.

- Easy to clean design: The interior of the cavity is smooth with

no dead corners. The material is mostly stainless steel (such as

304/316L), and the surface is polished to meet GMP and other

hygiene standards. It is convenient for disassembly and

maintenance.

4. Industry-specific applications

- It is particularly suitable for scenarios with high requirements

for uniformity of mixing and residue, such as tablet and granule

mixing in the pharmaceutical industry, additive blending in the

food industry, and catalyst preparation in the chemical field.

Product Parameters

| Model | V-30 | V-100 | V-200 | V-300 | V-500 | V-1000 | V-1500 | V-2000 | V-3000 | Total volume

(L) | 10-30 | 100 | 200 | 300 | 500 | 1000 | 1500 | 2000 | 3000 | | Effective volume

(L) | 5-15 | 50 | 100 | 150 | 250 | 500 | 750 | 1000 | 1500 | | Maximumloading

weight (kg) | 5-20 | 40 | 80 | 120 | 200 | 400 | 600 | 800 | 1200 | | Spindle

speed (RPM) | 29 | 1-12 | 1-12 | 1-12 | 1-12 | 1-12 | 1-9 | 1-9 | 1-9 | | Motor

power (kw) | 0.55 | 0.75 | 1.1 | 1.5 | 2.2 | 3 | 4 | 5.5 | 7.5 | | | Input power | 220V | 380V | 380V | 380V | 380V | 380V | 380V | 380V | 380V | Total turning

height (mm) | 1200 | 1500 | 1650 | 1800 | 2100 | 2400 | 2700 | 3000 | 3200 | | | Weight (kg) | 120 | 500 | 600 | 700 | 800 | 1000 | 1150 | 1400 | 2300 | Overall

dimension (mm)

L / w / h | 800*

400*

1200 | 1800*

600*

1500 | 2200*

650*

1700 | 2320*

720*

1800 | 2450*

720*

2000 | 3000*

900*

2300 | 3300*

1200*

2600 | 3800*

1200*

2900 | 4100*

1800*

3100 | | | | More sizes can be customized |

|

Details Lmages

Product Shows

Packing & Delivery

Why Choose Us

About us

Company Profile

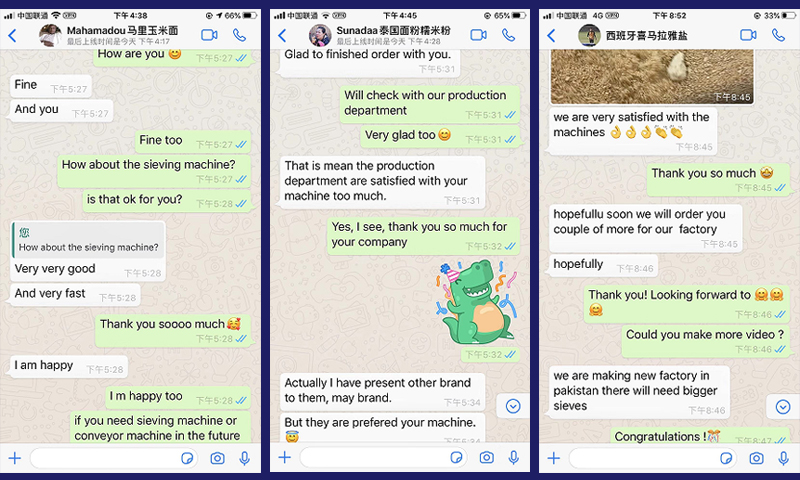

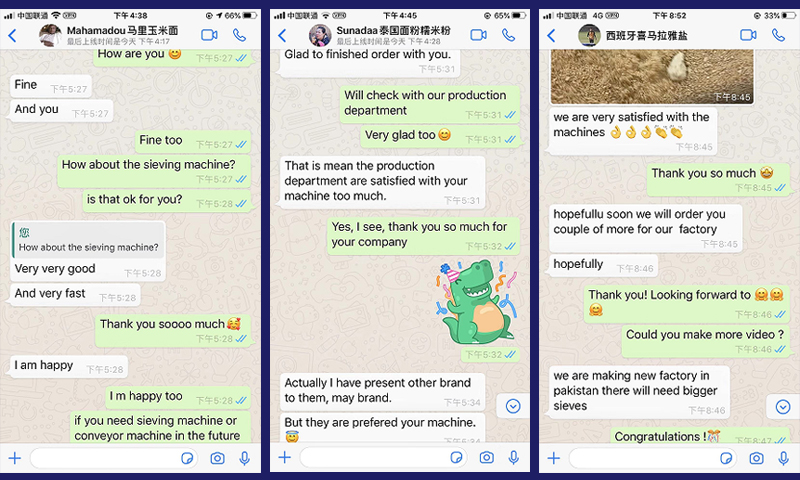

We have been specializing in the production of Screening and

conveying equipment for 13 years. China's vibrating screen industry

top three. And we have done matching and OEM for many large

companies. Including the world's top vibrating screen manufacturer,

Sweco, USA, we have OEM for his China region. And our products are

often exported to Australia, Thailand, Indonesia, New Zealand and

other countries.