Who are we:

EVERSUN Machinery, founded in 2003, is a professional manufacturer

of screening and conveying equipment in China. It is also

iso9001:2015 quality management system certification and CE

certification company.

Eversun Machinery is committed to providing screening and conveying

technology solutions to our customers. Whether you are in food,

chemical, pharmaceutical or other industries, whether you want to

separate solid particles from solid or liquid, we will provide

screening and transportation solutions according to the

characteristics of different industries and materials to meet the

requirements of customers. And improve efficiency and product

quality.

For screening and conveying solutions, please contact us at.

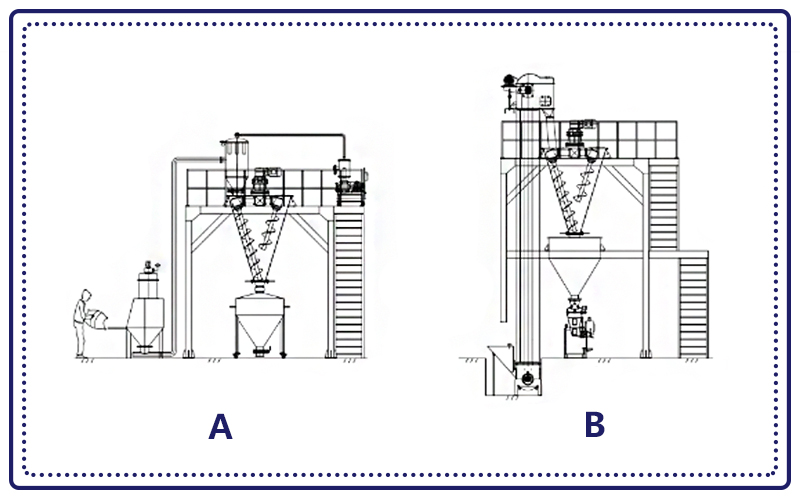

What do we produce:

Our products include: screening machine, drum screening machine,

ultrasonic vibrating screen, liquid filter, linear screening

machine, vacuum conveyor, dumping station, grinder, etc.

And can customize various machines.

Our services:

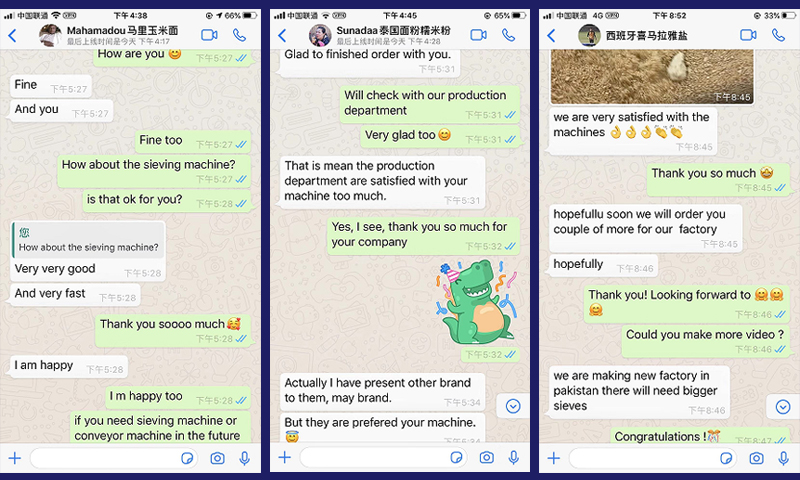

EVERSUN Yongsheng Machinery has the ability to serve customers all

over the world, whether it is on-site maintenance, installation and

commissioning, or after-sales accessories. And any electrical and

safety standards. Our price and delivery ability have also been

highly praised by customers

Professional OEM factory:

As one of the largest OEM factories in China, we provide about 5000

machines to more than 150 dealers, manufacturers and traders every

year, and provide a variety of reliable customized equipment to

help our customers build their own brands.