Conical mixer

Product Description

The conical mixer is a highly efficient mixing equipment with a

conical cylinder as its core structure, widely used for uniform

mixing of powder and granular materials. It features high mixing

efficiency, strong material adaptability (able to handle materials

prone to agglomeration or with small density differences), low

residue, compact structure, and easy operation. It is commonly

applied in industries such as chemical engineering,

pharmaceuticals, food, and building materials, and is particularly

suitable for small and medium batch mixing operations.

Working Principle

The working principle of the conical mixer is that the stirring

paddles rotating inside the cylinder lift the materials from the

bottom of the cone upwards. At the same time, by taking advantage

of the inclination angle of the cone and the gravity of the

materials, the materials spread outwards and slide down along the

cylinder wall during the upward movement, forming a circulating

convection motion. During this process, the materials are

constantly subjected to shearing, flipping by the paddles and

mutual collisions among different material particles. Eventually,

through repeated shearing, convection and diffusion, the materials

of different components are evenly mixed. This design not only

utilizes the active pushing force of mechanical power but also

completes the circulation with the help of the materials' own

gravity, enabling the materials to achieve a high degree of uniform

mixing in a relatively short time.

Product features

Good mixing effect: It can achieve uniform mixing of materials to a

high degree, suitable for powder and granular materials with small

density differences and prone to agglomeration.

Strong adaptability: It can handle dry powders and particles, and

when combined with accessories, it can mix paste-like materials

containing a small amount of liquid.

Low residue: The conical cylinder and reasonable blade structure

reduce material residue, are easy to clean, and meet high hygiene

requirements.

High efficiency: It can complete mixing in a short time and

effectively improve production efficiency.

Compact structure: Simple design, small floor space, easy

installation and maintenance.

Easy operation: Supports automatic control, simple process, easy to

operate, can reduce labor intensity.

Stable operation: Low vibration, low noise during operation,

reliable, and has a long service life.

Product Parameters

| Model | VBDS-180 | VBDS-300 | VBDS-500 | VBDS-1000 | VBDS-2000 | VBDS-3000 |

| Power(kw) | 1.1 | 1.1 | 2.2 | 4 | 7.5 | 11 |

| Capacity (kg/batch) | 40 | 60 | 100 | 200 | 400 | 600 |

| Total volume(m³) | 0.18 | 0.3 | 0.5 | 1 | 2 | 3 |

| Mixing time(min) | 4~8 | 6~10 | 6~10 | 6~10 | 6~10 | 6~10 |

| Speed(r/min) | 12 | 12 | 12 | 10 | 10 | 8 |

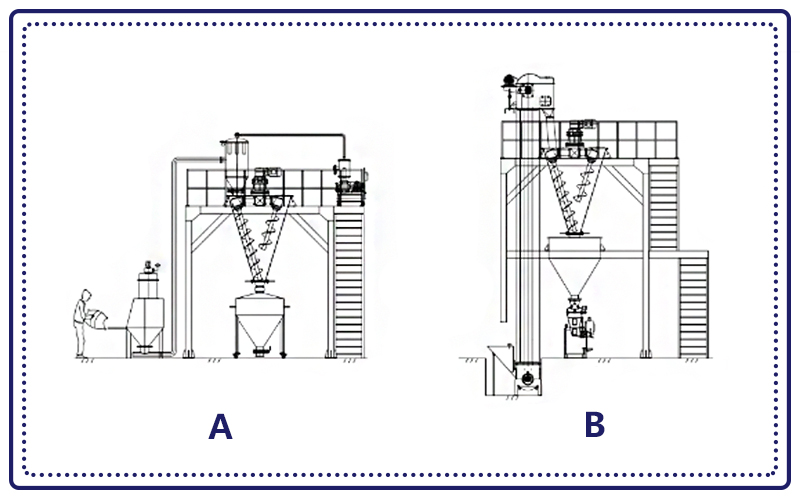

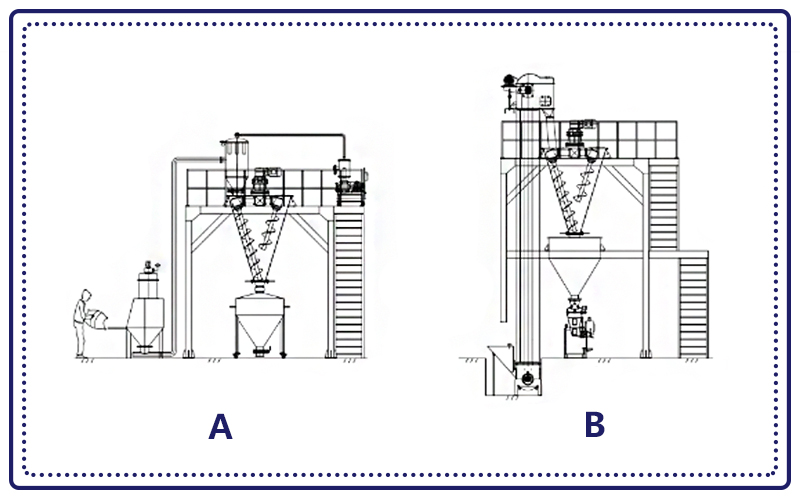

Production line schematic diagram

Configuration A: Manual feeding to the feeding station → Vacuum

feeder suction feeding → mixing → mobile silo.

Configuration B: Bucket lift feeding → Mixing → Transition silo →

packaging machine.

Details Lmages

Product Shows

Packing & Delivery

Why Choose Us

About us

Company Profile

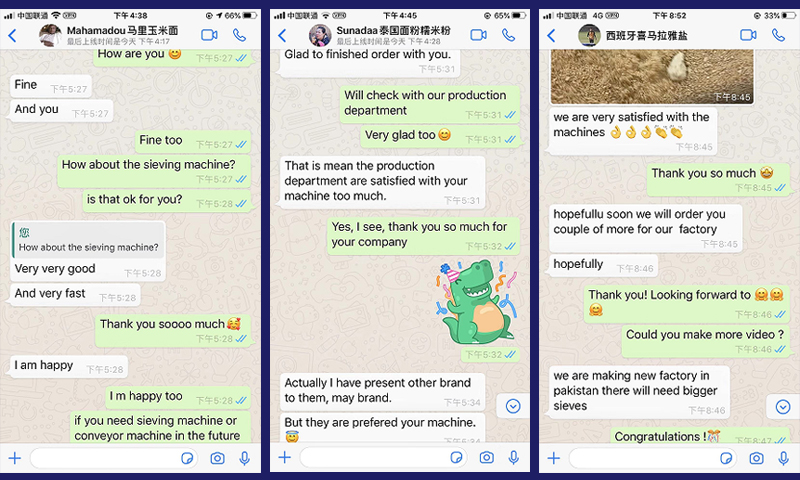

We have been specializing in the production of Screening and

conveying equipment for 13 years. China's vibrating screen industry

top three. And we have done matching and OEM for many large

companies. Including the world's top vibrating screen manufacturer,

Sweco, USA, we have OEM for his China region. And our products are

often exported to Australia, Thailand, Indonesia, New Zealand and

other countries.